Blister packaging

Integration of technology-based adherence monitoring and burgeoning R&D efforts for sustainable alternatives to plastic-based solutions emerge as game-changers for the blister packaging industry.

Packaging is an essential component of the supply chain for any industry that deals with the manufacturing and transport of products. For the pharmaceutical industry, in particular, packaging plays a key role in the drug delivery system as well as the marketing of new products.

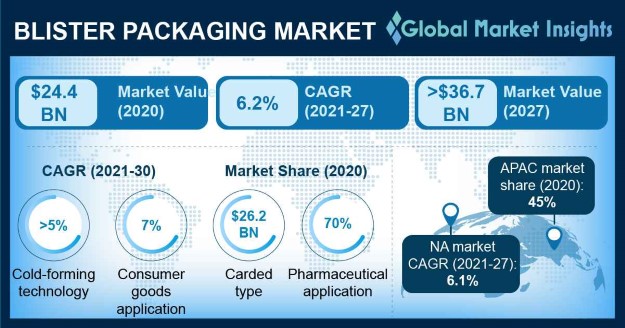

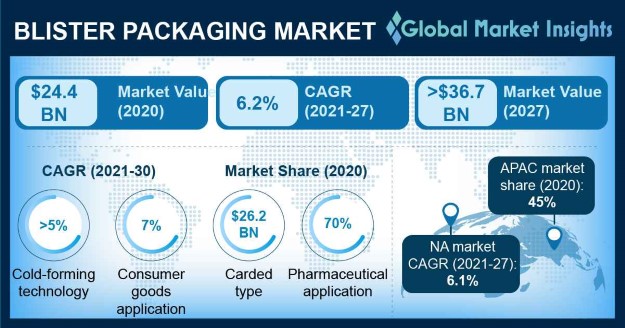

Over the years, the pharma sector has witnessed a significant revolution in packaging, blazing the trail for a new generation of advanced and “smarter” solutions. One of the most prominent breakthroughs in this revolution has been observed in the blister packaging market, which is set to exceed USD 36.7 billion by 2027, as per a Global Market Insights Inc. report.

Owing to the sensitive nature of healthcare and drug products, optimum care and protection are required for the solutions during transit. Pharmaceutical blister packaging solutions offer a viable solution to this issue, owing to beneficial attributes like versatility and transparency, among others.

While the medical industry has been the primary application area for blister packaging since its emergence in the mid-twentieth century, rapid technological advancements and persistent research efforts have also helped the solution expand across a wide array of industries in recent years. Blister card packages are emerging as a popular choice for brands looking for solutions that allow them to increase display visibility of their products whilst keeping them safe through storage in pre-formed rigid cavities and also cut back on waste generation in an era where sustainability is a key area of focus.

‘Smart” blister packaging solutions address burgeoning medication adherence challenge

Medication non-adherence is becoming a major pain point for the healthcare sector worldwide, asserting a strong impact not just on patient health but also financially. According to the New England Journal of Medicine, over 69% of medication-related hospitalizations each year are a result of poor adherence to medication regimens. Furthermore, estimates from the WHO (World Health Organization) have revealed that medication non-adherence contributes to almost 125,000 deaths annually, costing the healthcare industry nearly USD 100 billion.

Given this heavy burden, several advanced technologies have been introduced over the last decade to address this issue, from reminder mobile applications to complex medication dispensing devices for in-home use. The integration of smart technologies like Bluetooth, QR codes, and NFC, among others, is redefining the approach to packaging for pharmaceutical products by facilitating better inventory management and adjusting demand levels.

Connected adherence packaging especially is becoming a standard in the blister packaging industry. With the help of printed electronics with transmission capabilities, smart packaging allows care teams to monitor adherence data in real-time to detect whether patients have consumed the medication as well as to send reminders and notifications to caregivers and patients.

In November 2021, Palladio Group SpA launched a breakthrough technology plan dubbed PhutureMed, including a smart blister package designed to provide assistance to patients for drug analysis, with an electronic print for better access to clinical drug trials. Named PluggyMed, the new pharmaceutical blister packaging solution created in collaboration with Omnys was also equipped with a smartphone application to give patients a summary of their therapy regimen and allow them to keep track of correct medical dosages. Furthermore, through the use of conductive inks for printing, the solution was also developed to facilitate seamless interaction between a smart device and the blister package to monitor the medication adherence of patients.

3 innovative paper-based solutions supporting the blister packaging industry’s pivot toward sustainability

As sustainability concerns mount, major sectors in the global industrial landscape have started to make the shift toward eco-friendly packaging alternatives with higher concentrations of recycled and recyclable materials. The packaging industry is not immune to this trend, with several suppliers now facing the challenge of creating sustainable blister packaging options using environmentally sound materials.

According to estimates from Global Market Insights Inc., the blister packaging market from the paper & paperboard materials segment registered revenue worth over USD 3.2 billion in 2020. This growth is characterized by the emergence of paper-based packaging as a strong contender in the fight against plastic waste. To that end, major packaging manufacturers have begun to shift their efforts toward bringing innovative, paper-based blister packaging solutions to market, to cater to the sustainability needs of various sectors.

Sonoco Alloyd’s all-paper EnviroSense PaperBlister solution for retail packaging

In February 2020, the Alloyd division of packaging from Sonoco announced the launch of a new all-paper retail blister packaging solution, designed to serve as an alternative to conventional plastic-based thermoformed blister packages. Dubbed EnviroSense PaperBlister, the plastic-free solution demonstrated multiple benefits, from recyclability in the paper stream to low VOC emission due to the use of water-based sealing technology, to better marketing messaging via increased billboard space, and more.

Unlike traditional plastic-based blister packaging products, which rely on three times more shipping cartons, the EnviroSense PaperBlister packaging was designed by the company to reduce packaging material and weight. By enabling more packages per truckload and consequently more deliveries for the same amount of product, this would eventually reduce waste and minimize the impact of the retail industry on the environment.

Henkel’s plastic-free blister packaging for Pritt consumer adhesive brand

In June 2022, Henkel introduced its new plastic-free blister packaging for its global consumer adhesives portfolio, including the Pritt glue stick range. Crafted using a minimum of 85% recycled material and designed to be fully recyclable, the new paper-based blister packs represent an effort from the firm to mitigate over 1,000 tons of plastic per year.

The new concept was also in line with the firm’s ambition to achieve sustainability and circularity in its packaging solutions by 2025, thus adding weight to the concept that the use of paper & paperboard in the development of blister packaging and other solutions will usher the global economy closer to a circular economy.

Huhtamaki & Syntegon’s industry-first paper-based Push Tab tablet packaging

The success of paper-based blister packaging is also characterized by several groundbreaking innovations in healthcare and pharmaceutical sectors emerging across the globe, one of which was Huhtamaki and Syntegon’s collaborative launch of the new Push Tab solution in July 2021. Touted as the first paper-based packaging for tablets in the industry, the solution was made using 75% renewable certified paper and was crafted specifically to ensure maximum compliance with the stringent safety standards for pharmaceutical packaging.

By offering a sustainable alternative to conventional thermoformed PVC and aluminum-based push-through packaging, the Push Tab solution has revolutionized the blister packaging value chain by mitigating environmental impact, reaffirming the commitment of the entities to advancing sustainability across the packaging spectrum. By and large, of all the prominent trends sweeping across the packaging sector in recent years, the pivot of manufacturing industries towards the development of next-generation products is promoting the emergence of advanced packaging solutions in recent times.

With versatile and sturdy solutions gaining prominence not only for protection but also for better marketing visibility and sustainability, the blister packaging industry seems to be headed for a bright future as the product is becoming the preferred choice in the modern packaging ecosystem.

Disclaimer: This post is for the information and educational purpose.