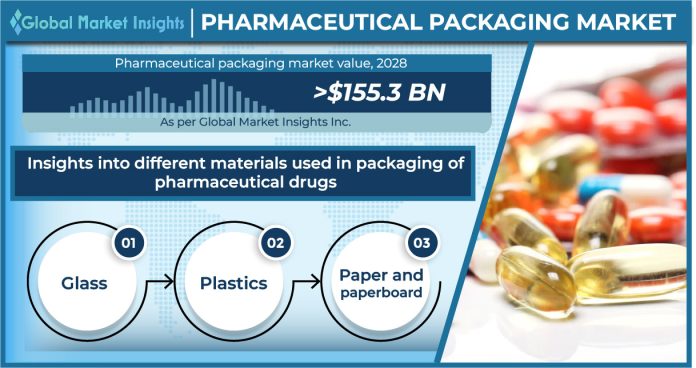

Pharmaceutical Packaging Market

“The pharmaceutical packaging market is witnessing a steady development with the demand for new drugs and prevalence of chronic diseases. The industry is anticipated to be worth over USD 155.3 billion by 2028.”

Pharmaceutical businesses are creating a prolific demand for reliable and speedy packaging solutions that offer a combination of product protection, tamper-proof features, quality, ingredient labelling, and patient access.

Constant upgrades in the pharmaceutical packaging industry would open new prospects for the leading market players to fortify their positions worldwide. One of these advancements is the production of biodegradable and sustainable packaging for medicines.

In 2021, Amcor- a pioneer in packaging solutions- announced the addition of more sustainable and new High Shield laminates to its robust pharmaceutical packaging profile. According to the officials, the novel carbon, recycle-ready packaging options deliver on 2 fronts- addressing optimum barrier and performance requirements need for the industry: and supporting pharmaceutical companies’ recyclability targets.

In yet another instance, Natupharma introduced a fully biodegradable and recyclable plastic packaging solution for use across the healthcare and pharma sectors. Post the initial testing to develop environmentally friendly packaging, scientists made use of a biodegradable plastic additive which they merged with sugarcane to manufacture a greener plastic.

Experts speculate the new green polymer to degrade in 10 years, hence being a value addition to the pharmaceutical packaging industry. With such developments taking place globally, the solution providers are now considering the use of prominent materials for the production of pharma packaging that can be both environmentally friendly and provide ease of use to consumers. Some of these materials include plastics, glass, paper and paperboard, metal, and others.

Insights into different materials used in packaging of pharmaceutical drugs

Glass

100% recyclable material, glass is one of the highly preferred materials across the pharmaceutical segment for its use as a packaging solution. This can be accounted for its umpteen benefits including high resistance to temperature, non-reactivity to chemicals, resistance to leak, and ease of sterilization and visibility.

Currently, the demand for glass as a packaging material is gaining widespread popularity in the era of COVID-19. Reason? Surging demand for glass vials to store coronavirus vaccines. Most vials used for pharmaceutical packaging are produced from borosilicate glass that is composed primarily of 80% silica and 10% boric oxide.

According to reliable reports, until March 2022, the world witnessed the administration of nearly 11.29 billion doses of coronavirus vaccines. This produces an innate need for glass vials to generate more doses to ensure a 100% inoculation of the global population. And in this regard, Schott- a promising glassmaker- in 2021 announced delivering glass vials for 1 billion doses of the COVID-19 vaccines.

The company also pointed out that it had delivered vials for more than 2 billion vaccine doses during 2021 around the world with emphasis on Europe, the US, and Asia. With the demand for glass packaging accounting for a considerable share in the global pharmaceutical industry, different pharma leaders are now upping their games to announce strategic collaborations and product developments in the space. To illustrate, Bormioli Pharma declared a series of partnerships aimed at enhancing the sustainability and performance of glass used for pharmaceutical applications.

Plastic

Second to glass, the plastic packaging material is growing in demand across the pharmaceutical sector owing to several advantages over glass containers. These containers are usually made of materials that do not include in their composition any substance that can affect the stability or efficacy of the formulation or present a risk of toxicity.

Plastics generally consist of about 20 percent of the weight of all pharmaceutical packaging. Plastics like high-density polyethylene and acrylic are used for fluid handling applications within the pharmaceutical sector. The material plays an impeccable role in keeping medicine safe for use that needs to stand up to the sterilization process, offer protection against water damage and UV, and non-reactivity with chemicals.

Various governments and companies are now working towards making use of recycled plastics as packaging for pharmaceutical medicines and supplies. In 2020, the British Plastics Federation released a document with guidelines that focused on how recycled plastic can be used in the pharmaceutical industry.

One of the largely used packaging in the pharma sector is blister packaging. And to much surprise, blister packaging is also comprised of PVC or PET plastic packaging. However, ongoing concerns around plastic pollution and plastic waste are diverting the attention of pharma companies toward the launch of sustainable plastic materials for blister packages.

For instance, Astellas, in 2021, publicized its decision of using biomass plastics made from plant-extracted materials in blister packages for storage of pharmaceutical products. For the unversed, this novel invention emerges to be the globe’s foremost use of biomass plastic for drug blister packages.

Paper and paperboard

The pharmaceutical industry is observing keen interest towards the use of paper and paperboard packaging materials for pharmaceutical drugs. The use of these materials remains a vital part of pharmaceutical packaging despite the fact that paper is rarely used on its own for a primary package. Essentially, paperboard cartons are being widely used in the industry for a number of reasons such as offering better display of stock items, increasing the display area, and collating of leaflets that would otherwise be difficult to attach to containers.

Industry analysts are of the opinion that the market value of paper & paperboard pharmaceutical packaging segment would surge beyond USD 11.9 billion by 2028. Recyclability, easy printing and product labelling, lightweight nature, cost-effective manufacturing are some of the key factors augmenting the consumption of the materials.

The pharmaceutical industry is on a progressive journey with innovations and developments being the prime accelerators of this growth trajectory. Moreover, the recent outbreak of the coronavirus pandemic has opened new growth avenues for the industry leaders, leading to a positive inclination towards safe packaging solutions. Lower toxicity, resistance to chemicals, heat, and temperature, tamper-proof, and cost-effective packaging are the current needs of the pharma leaders. For meeting these requirements, companies are trying to experiment with different packaging materials for medicine and accessory packaging solutions that best suit the consumers.

Read More: https://www.gminsights.com/industry-analysis/pharmaceutical-packaging-market

To know about cyber grooming, read https://innovareacademics.in/blog/do-you-know-what-cyber-grooming-is/

Pharmaceutical packaging market is very huge and with the time, it needs very deep knowledge. Pharmaceutical packaging market should be seen as an opportunity to gain growth.