Corrugated Packaging Market

The expansion of the eCommerce sector has impacted numerous verticals in recent times. In tandem with the global shift towards sustainability, the proliferation of this business has led marketplaces such as the corrugated packaging industry to accumulate substantial monetary gains. The momentum built up during the COVID-19 pandemic, when eCommerce and online retail flourished, will continue to drive the demand for corrugated packaging in the coming years.

The fact that corrugated packaging materials are completely recyclable is rapidly pushing the industry to the forefront of the global drive toward green packaging solutions. In their mission to reduce their respective carbon footprints, several industry players have been turning to corrugated packaging as the most effective and cost-efficient way to make their supply chains more sustainable for the planet.

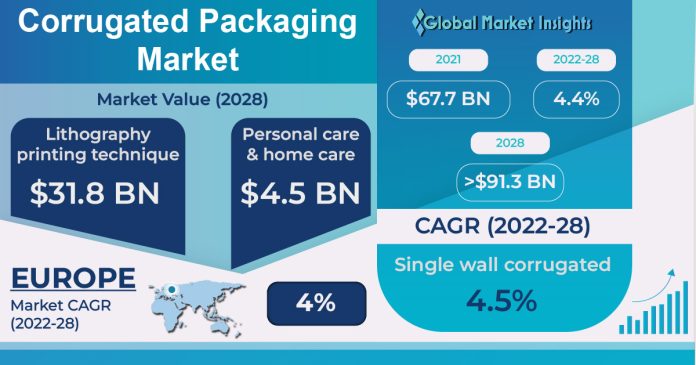

It comes as no surprise, therefore, that a recent report by Global Market Insights Inc. estimates the corrugated packaging market to surpass a valuation of more than $91.3 billion by 2028. The following paragraphs explore a few key factors that have been instrumental in pushing the demand for this product.

4 major factors are here which placing corrugated packaging market on the top of green packaging revolution.

Impact of the COVID-19 pandemic on corrugated packaging demand

During the COVID-19 pandemic, and through its subsequent recovery period, eCommerce as a sector has witnessed significant growth. Being one of the primary revenue generators for the packaging market, it has allowed the industry to thrive, especially during a period that proved tumultuous for many businesses.

Back in 2021, Volkan Bozkir, the President of UN General Assembly, stated that UNCTAD estimates expect the ongoing eCommerce expansion trend to continue through the world’s COVID-19 recovery. This effectively ensured a notable growth impetus for the corrugated packaging market then – a trend that will continue in 2022 and beyond.

Growing global disdain for plastic and the mission to find the right alternatives

A leading factor that is making the case for corrugated packaging is the growing global disdain for plastic and its proclivity to end up in the earth’s rivers and oceans, irreversibly damaging ecosystems in the process.

Plastic, once considered a wonder material, is harming the planet in more ways than one. Recent studies have discovered the existence of micro-plastics in the human body, with many clinical efforts currently underway to understand what impact they might have on our health.

According to National Geographic, more than 40% of plastic is only used once and then discarded, with packaging materials being the leading contributors to this statistic. With each such discovery, consumer awareness about the harm plastic packaging causes keeps increasing, generating momentum that calls for change. As more consumers began to actively advocate against their use of plastics, global brands have started replacing plastic packaging, one of the most commonly discarded plastic products, with sustainable alternatives.

Affordability of Flexography creating more impetus

Flexography is among the most commonly used packaging printing methods. Manufacturers typically use the technique to print on stand-up pouches and corrugated boxes. The method is also preferred among industry players owing to its affordability, as it greatly brings down the printing as well as tooling costs. Flexography also boasts of quicker turnround time and compatibility with oil and water-based inks. Efforts to improving the recyclability of packaging solutions have pushed brands and major online retailers toward paper-based packaging. The cost-savings offered by flexography are thus providing further impetus for the adoption of corrugated solutions, driving market expansion.

This is also interesting: CDMOs And Their Importance In Tech Startups

Strong demand from the global agriculture sector

Agriculture industry players and grocery retailers across the globe are always on the lookout for ways to enhance their profits by lowering costs throughout the entirety of their distribution channels. Logistics packaging is among the key areas that retailers scrutinize to obtain possible cost savings.

Recent case studies commissioned by Corrugated.org found that corrugated packaging enabled significant cost savings in produce shipping, offering better profit margins to retailers and farmers. The case studies found that shipping produce such as onions and strawberries in corrugated boxes instead of reusable plastic containers (RPCS) offered annual cost savings of 10.4% and $6.6 million, respectively.

A major issue with logistics packaging for products such as RPCS is the high cost incurred during back-hauling, i.e., when shipping the containers back to the point of origin or the next point of utilization.

In fact, as per Corrugated.org case study, when shipping 144 million pounds of strawberries from California to Ohio, the retailer incurred over $8.3 million in backhauling and crate handling, cleaning costs. However, the retailer was able to completely avoid these costs when shipping the strawberries using corrugated boxes, primarily owing to the fact that the boxes did not require back-hauling.

Final thoughts

Fostered by the unique blend of post-pandemic eCommerce industry scenario and the global shift away from plastics, the corrugated packaging industry is likely to witness substantial growth by 2028. Meanwhile, the benefits of corrugated packages in terms of cost savings make strong arguments for product adoption, further benefiting the market scenario for the future.

Disclaimer: This post of Corrugated Packaging Market is for the knowledge purpose.

More to Read: How to Create Digital Health ID online: ABHA Number? 2022